1.. 095000-5741 CR Fuel Injector Technical Support

1.1.095000-5741 CR Fuel Injector Part Number Location

E.g.:See the CR fuel injector part number as follows:

Pic No.1

| No. | Name |

| A | brand, logo, part number,

series number |

| B | nozzle part number |

1.2.095000-5741 Diesel Injection Application Scenarios

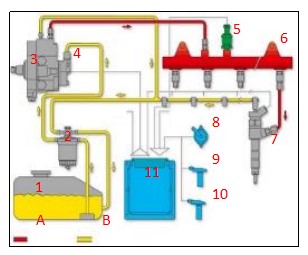

Common rail system is an oil supply method refers to the Fuel oil from the fuel tank sucked out by the gear pump through the oil-water separator and the gear pump to Fuel fine filter, high-pressure pump, common rail pipe, and diesel injection, all together with the closed-loop fuel supply system composed of sensors and ECU that completely separates the generation of injection pressure and the injection process from each other.

Pic No.2

| No. | Name | No. | Name | No. | Name |

| 1 | Tank | 6 | Common Rail Pipe | 11 | ECU Electronic Control Unit |

| 2 | Fuel Filter | 7 | Diesel Injection | A | High Pressure Oil Circuit |

| 3 | High-Pressure Pump | 8 | Accelerator Pedal | B | Low Pressure Oil Circuit |

| 4 | Fuel Gear Pump | 9 | Engine Crankshaft Sensor | / | / |

| 5 | Common Rail

Pressure Sensor |

10 | Camshaft Sensor | / | / |

1.3. Reasons for 095000-5741 Diesel Injection Not Working Normally

- There is air in the oil circuit of the engine fuel system.

- Vehicle oil pump oil supply system is not normal.

- Engine common rail system oil leakage or pressure limiting valve is damaged.

- There is a short circuit, cutting out and poor contact in the wiring harness connected to the diesel injectionof the vehicle.

- The long-term placement of the diesel injectioncauses the anti-rust oil to solidify, and the internal components are stuck or the oil holes are blocked.

- Before installing, carefully check whether other components in the common rail system except thediesel injections are damaged so as to prevent the diesel injectionfrom not working properly after being replaced.

1.4.095000-5741 Diesel Injection Storage Standard

The warehouse and cargo yard where the diesel injection is stored should be kept clean and dry, and away from the factory buildings that generate harmful gases and dust; do not mix with acid, alkali, salt and other substances; the storage place should have a good drainage system; the cargo yard should be flattened with gravel or furnace ash etc. to enhance the water permeability of the surface layer to keep the reservoir area dry.

- Strict Requirementsof Warehousing

Strict inspections should be carried out when the diesel injections are put into storage, the surface cleaning work should be done well to remove water traces, oil stains, ash and other dirt, remove the rust and do anti-rust treatment in time. Packaged diesel injections must be protected from damage.

- Keep the warehouse dry and preventing moisture

The relative humidity is usually below 70% for the diesel injections placed in the room, and the corrosion of the diesel injections is significantly reduced.

Diesel injections must be stored in the warehouse, and they are forbidden to store in the same warehouse with commodities with high water content.

After the diesel injection is exposed to rain, the corrosion rate will increase significantly. The purpose of sealing is to isolate the diesel injection from rainwater and humid air, so the warehouse window should be checked in time to avoid rainwater entering the warehouse.

If the diesel injection package is damaged, it should be repaired or replaced; when the package is damp, the packaging material should be dried; if the original anti-corrosion and oil applied at the factory is found to be damaged or dried up, it should be cleaned and re-applied oil in time.

- It is forbidden to leave the diesel injectionexposed in the air for a long time.

- It is forbidden to store acid, alkali, saltand other substances together with the diesel injection.

- The unpacked diesel injectionmust be rust-proof during secondary storage.

2. Copyright Statement

All the content in ”095000-5741 Diesel Injection Encyclopedia” belong to www.dieselinjections.com and is protected by the Copyright Law of the People’s Republic of China, international copyright treaties, and related laws and regulations on intellectual property protection. Without written authorization from www.dieselinjections.com, no media or individual may use the content in this passage for any commercial purposes (including but not limited to modifying, copying, intercepting, compiling, uploading, reproducing, and disseminating) in any way or medium. Otherwise it will be deemed as infringement, www.dieselinjections.com reserves the right to pursue its legal responsibilities in accordance with the law.

If you have any questions, please contact us at hison@shumatt.com.